hours at maximum load

Each individual cog tooth undergoes 3.6 million load cycles over the course of 300 hours of stationary operation.

million cycles

The endurance test. To test fatigue strength, the gearbox shafts are torqued 60 million times.

Kilometers in 2 Weeks

By applying a range of defined load force cycles we can simulate more than 60,000 kilometres of riding in less than two weeks.

Every Pinion gearbox guarantees

the highest quality and reliability

Pinion gearboxes are made to last. It is not uncommon for gearboxes to accumulate over 100,000 km! During endurance testing, we subject gearboxes to an equivalent of 60,000 kilometres of riding, but the service life of Pinion gearboxes extends far beyond 60,000 kilometres. This is proven by countless Pinion gearbox equipped bicycles in use around the world.

Load test

Dynamic load testing ensures gearbox shafts withstand

bending and torsion load tests up to 250 Nm.

bending and torsion load tests up to 250 Nm.

Pinion gearboxes undergo testing in our own rigs. They are also subjected

to established test procedures at independent test institutes.

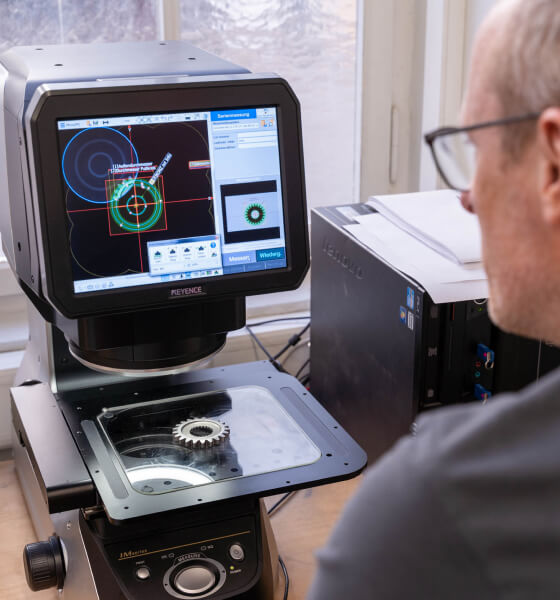

Runout check

Gearbox shafts are subjected to a concentricity check.

This test is part of the quality control procedure which

ensures fatigue-proof construction.

This test is part of the quality control procedure which

ensures fatigue-proof construction.

Tight tolerances

Exacting tolerances, accuracy, and precision manufacturing

ensure the smoothest operation of the assembly as a whole.

“I use my bike every day. Commuting, and a few bike trips a year mean I put a lot of kilometres on the gearbox, year after year. After racking up 100,000 km I registered my P1.18 gearbox for the Pinion Care factory inspection. I am completely thrilled – the difference is huge! The gearbox runs better than ever!”

Dieter S., confident all-weather rider

Stay in touch with us

PINION NEWSLETTER

Receive special offers, exclusive product news and event information directly in your inbox. Sign up now! Our data protection policy applies.

Unique

DIRECT

Acclaimed

Frequenty