Pinion Gearbox Technology

Pinion gearboxes shift the best bikes in the world. A reliable and low-maintenance shifting system for bicycles and E-bikes. Learn how Pinion technology works.

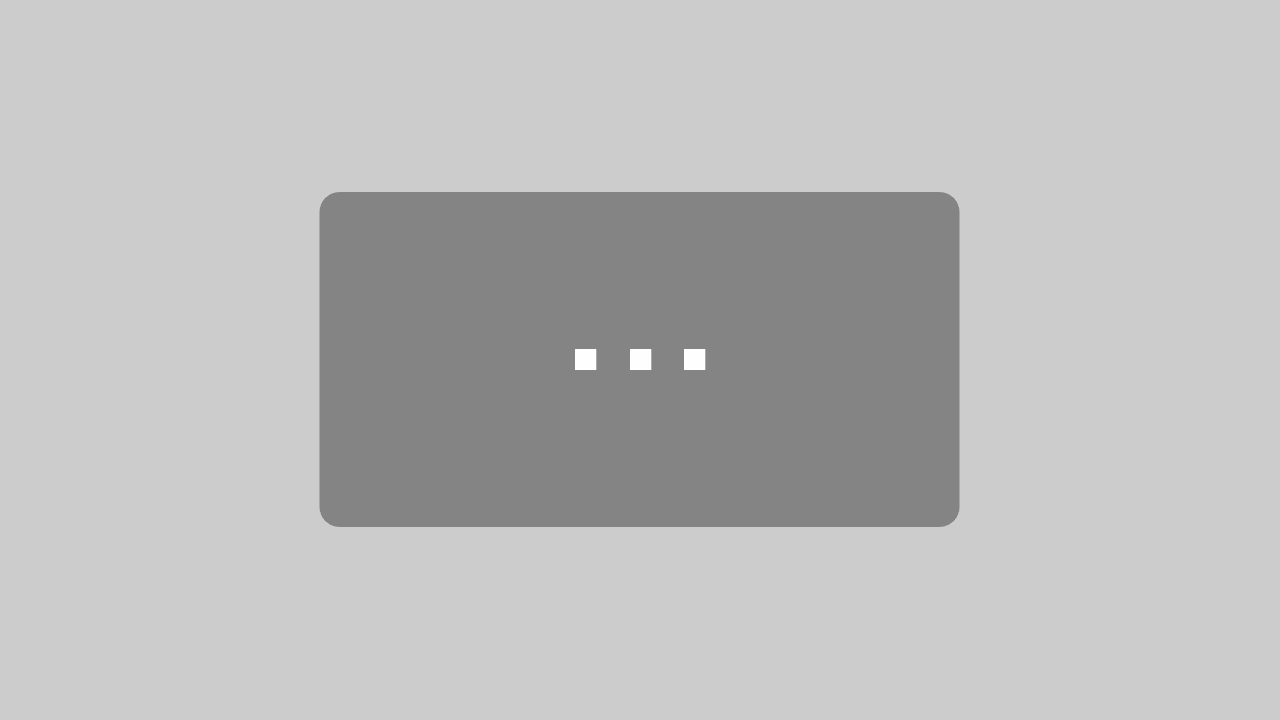

Proven automotive transmission

technology for bicycles

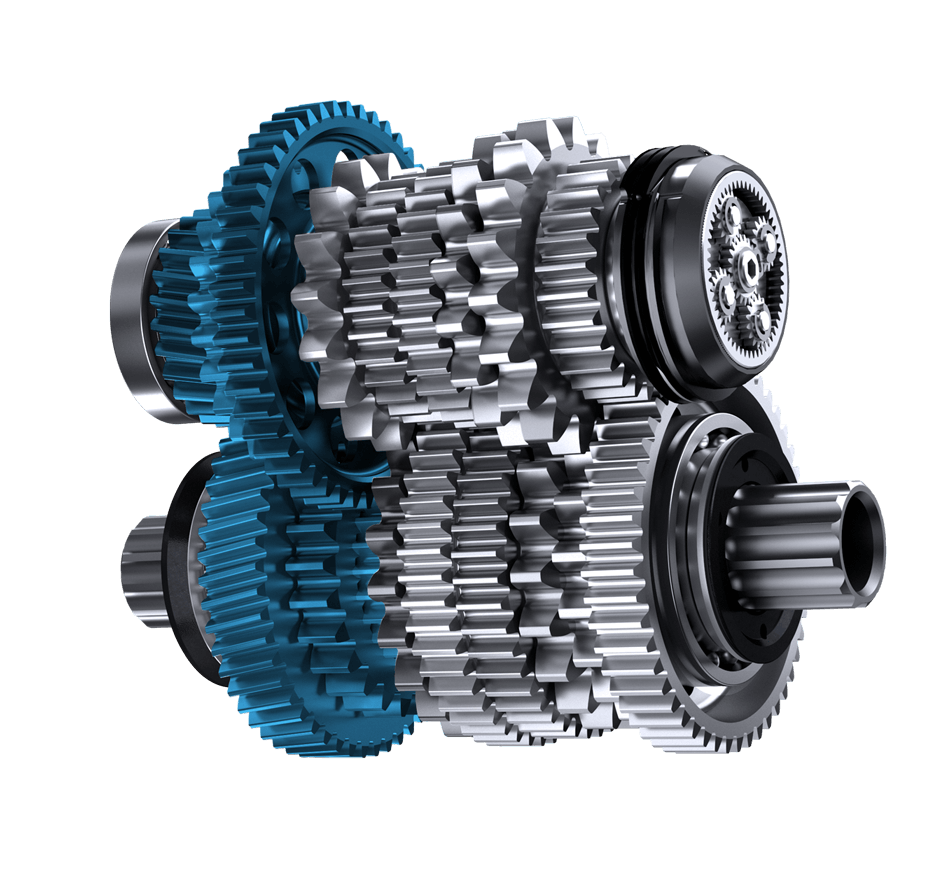

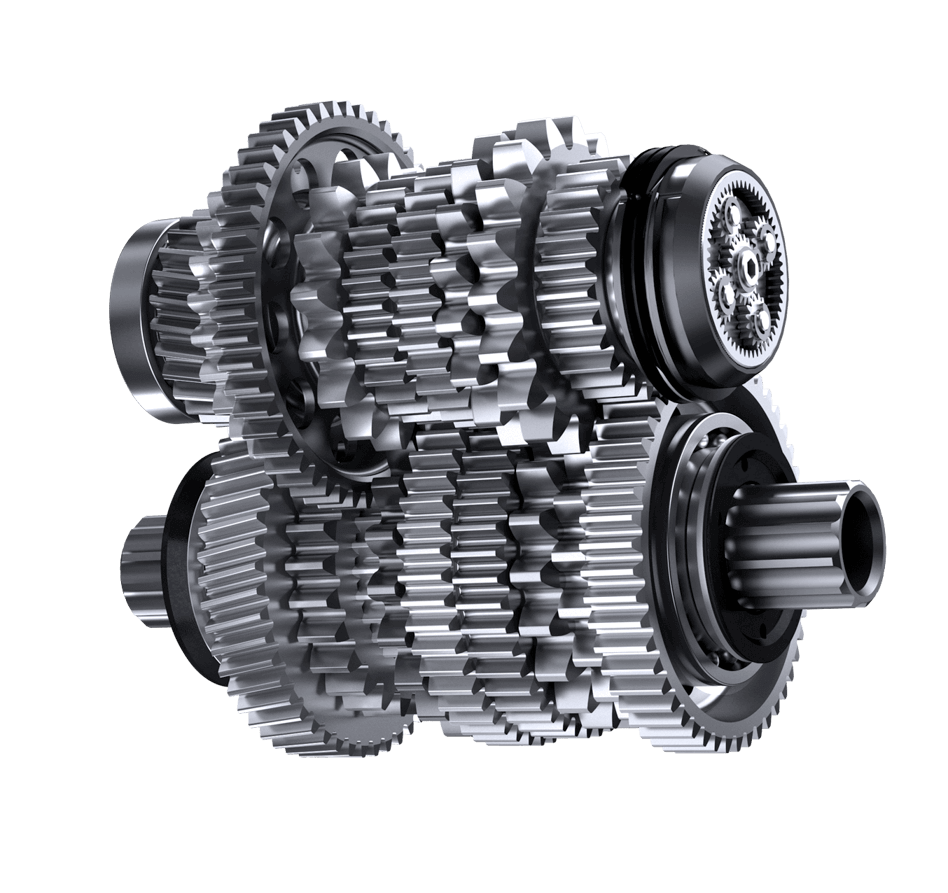

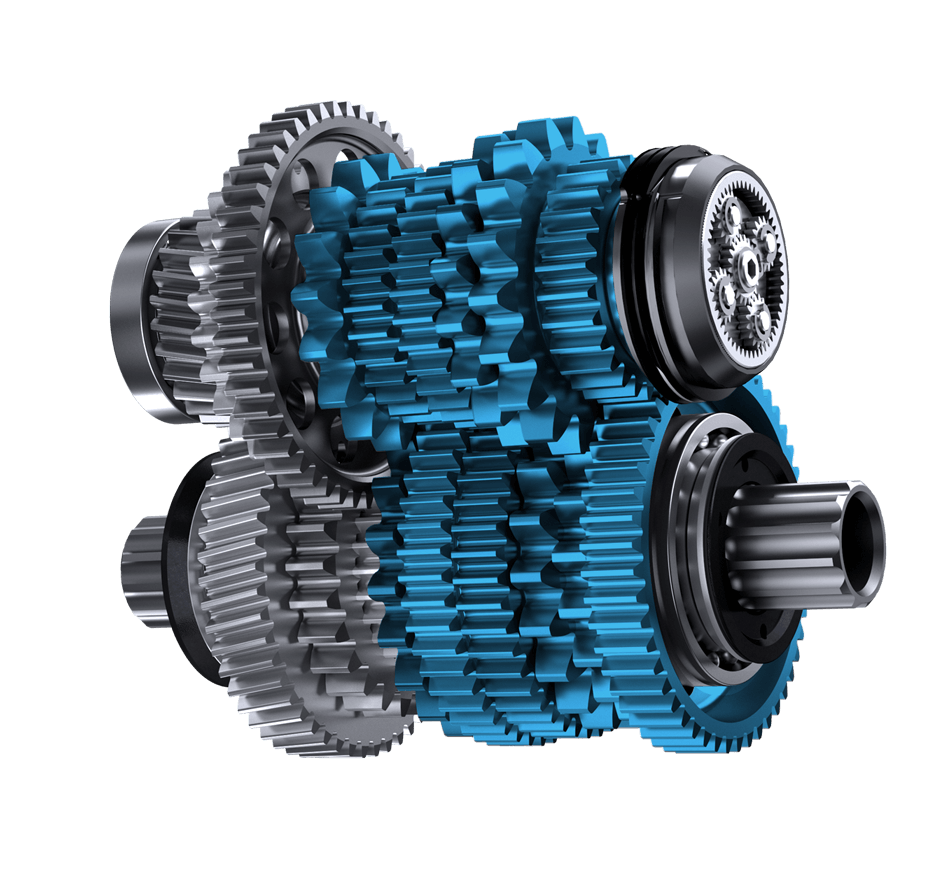

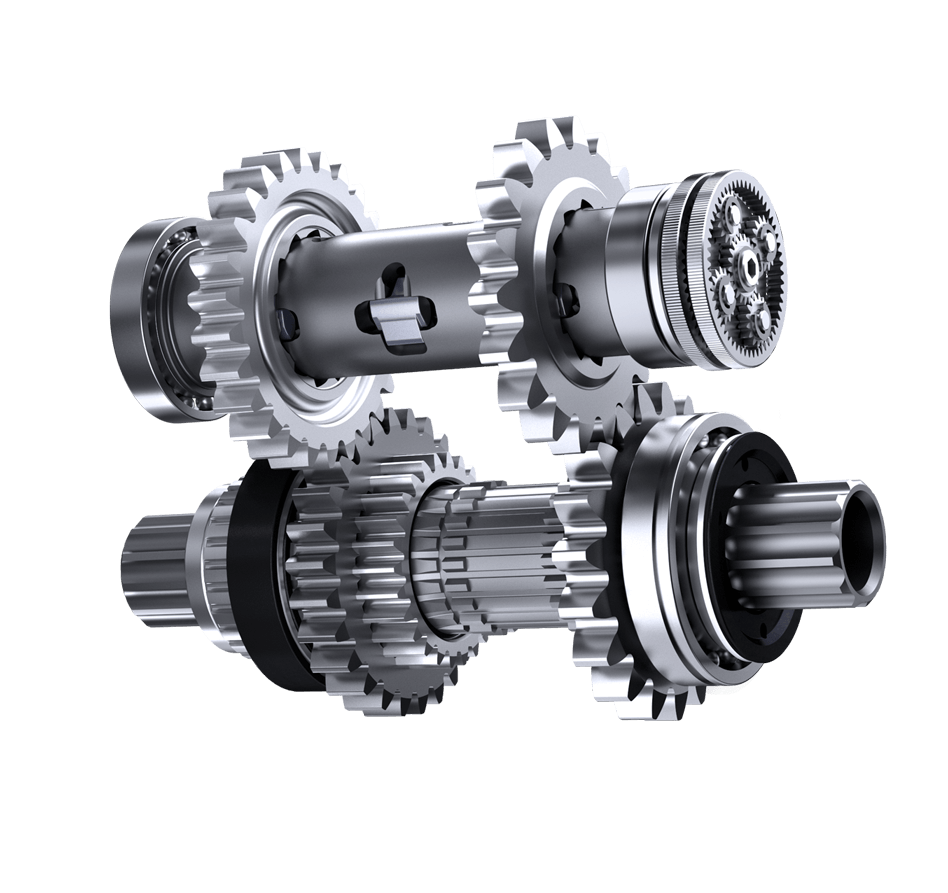

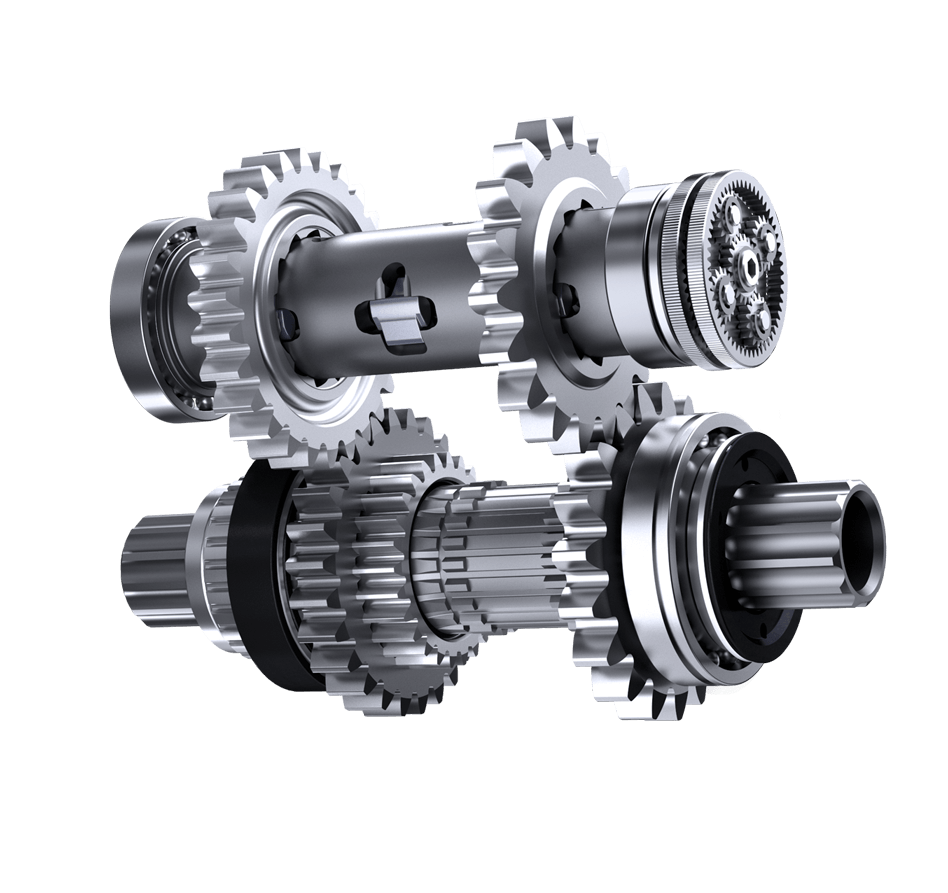

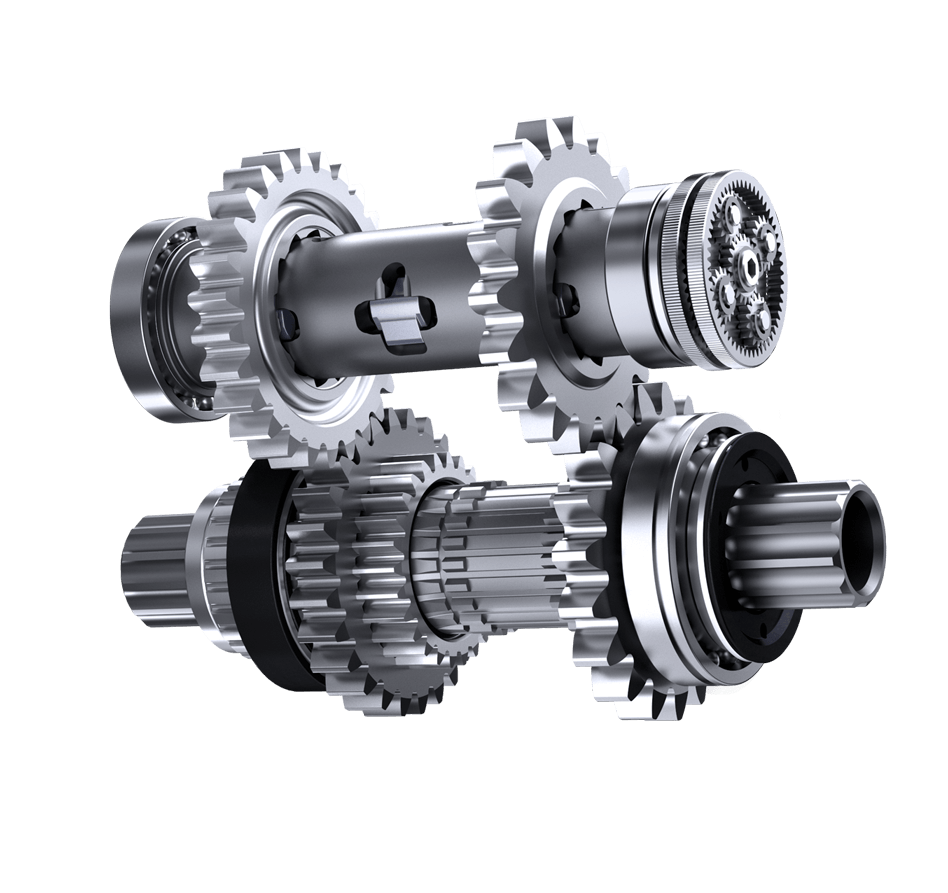

Modeled after proven automobile transmission technology, Pinion gearboxes use spur gearing with two sub-units connected in sequence. The individual gear ratios are derived by matching the two sub-units with various cog pairings. The steps between gears are evenly spaced and an ergonomically sensible gear ratio range is built specific to the area of application.

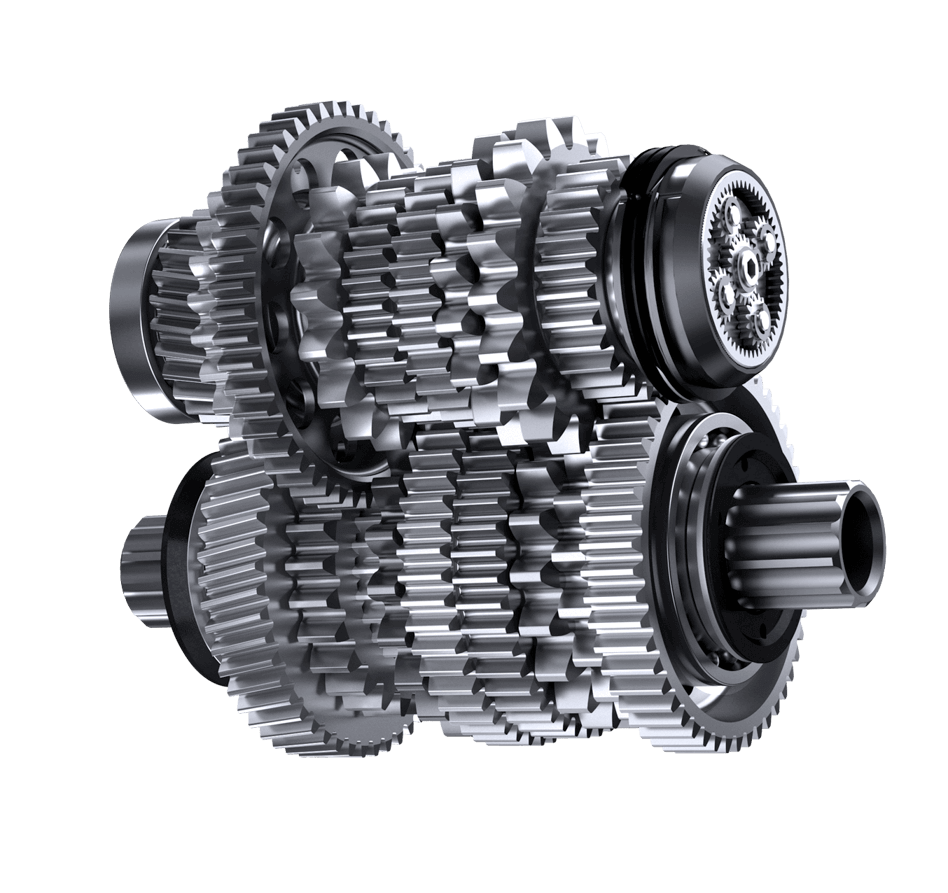

1. Sub-unit

First is a finely graduated sub-unit with 6 gears.

This is where finely stepped gear shifting takes place.

2. Sub-unit

In the second sub-unit, the gears

of the first sub-unit are multiplied.

This results in the corresponding

gear ratio range of the gearbox.

2. Sub-unit

In the second sub-unit, the gears

of the first sub-unit are multiplied.

This results in the corresponding

gear ratio range of the gearbox.

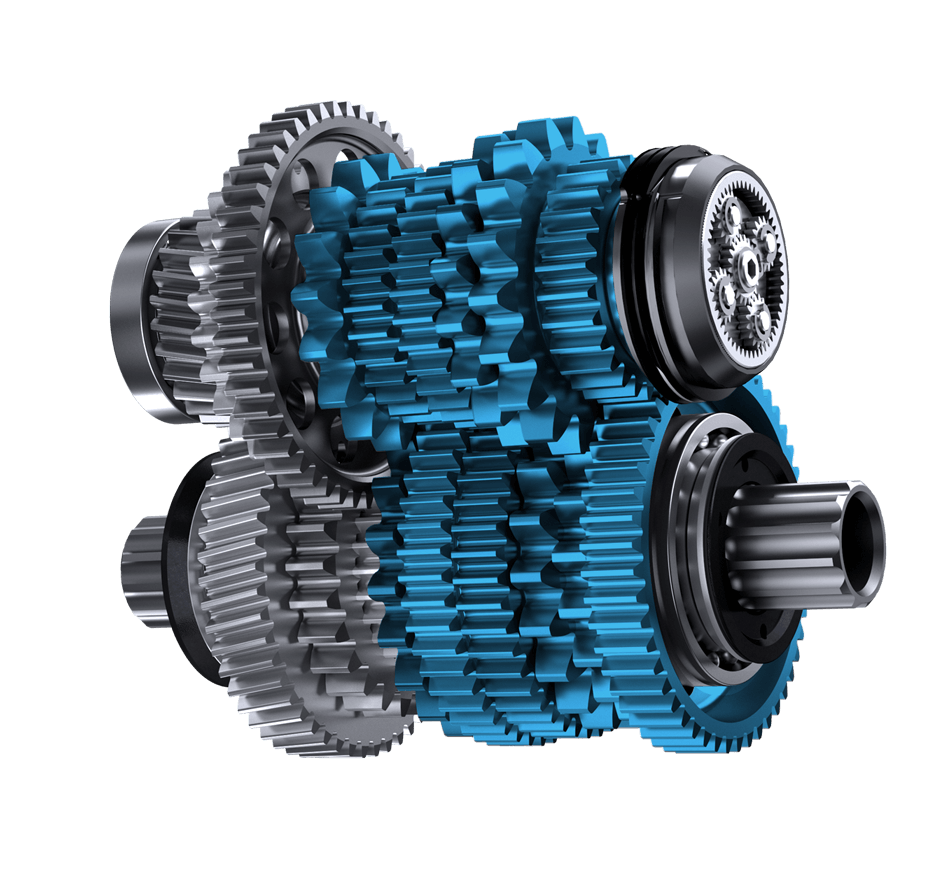

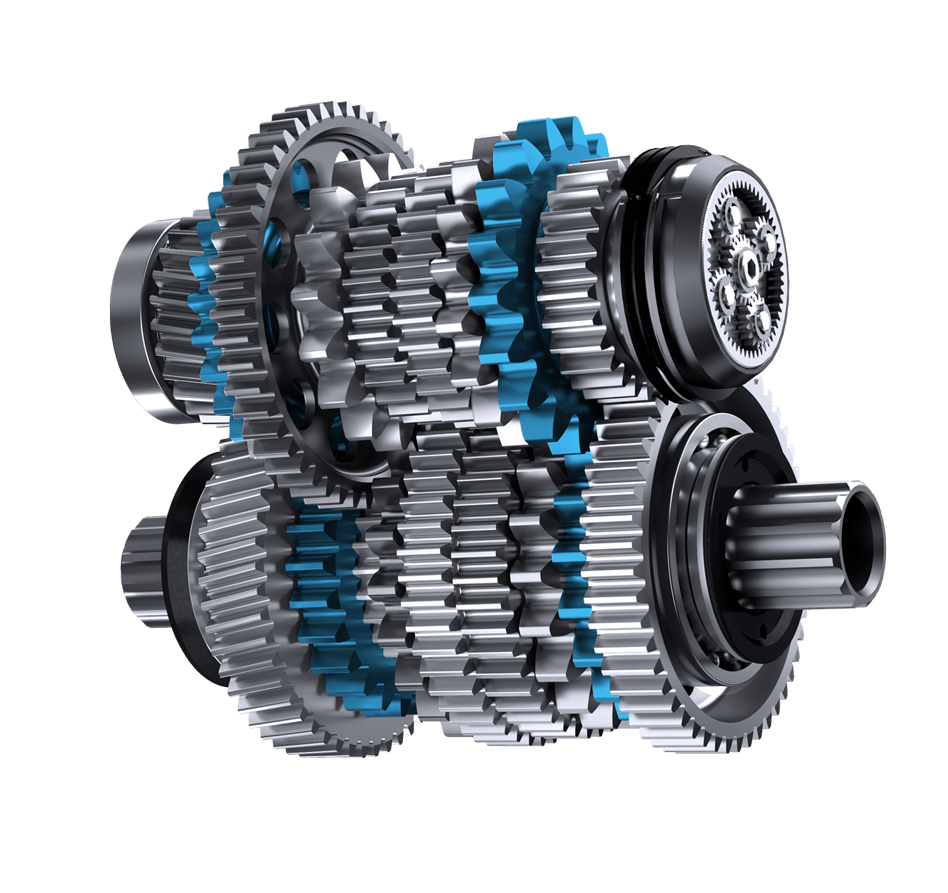

Engagement Gear

Here the 7th gear is engaged. The

two meshed gear pairs from the

sub-units are shown, which transfer

pedaling forces. The other cogs spin

freely and without resistance.

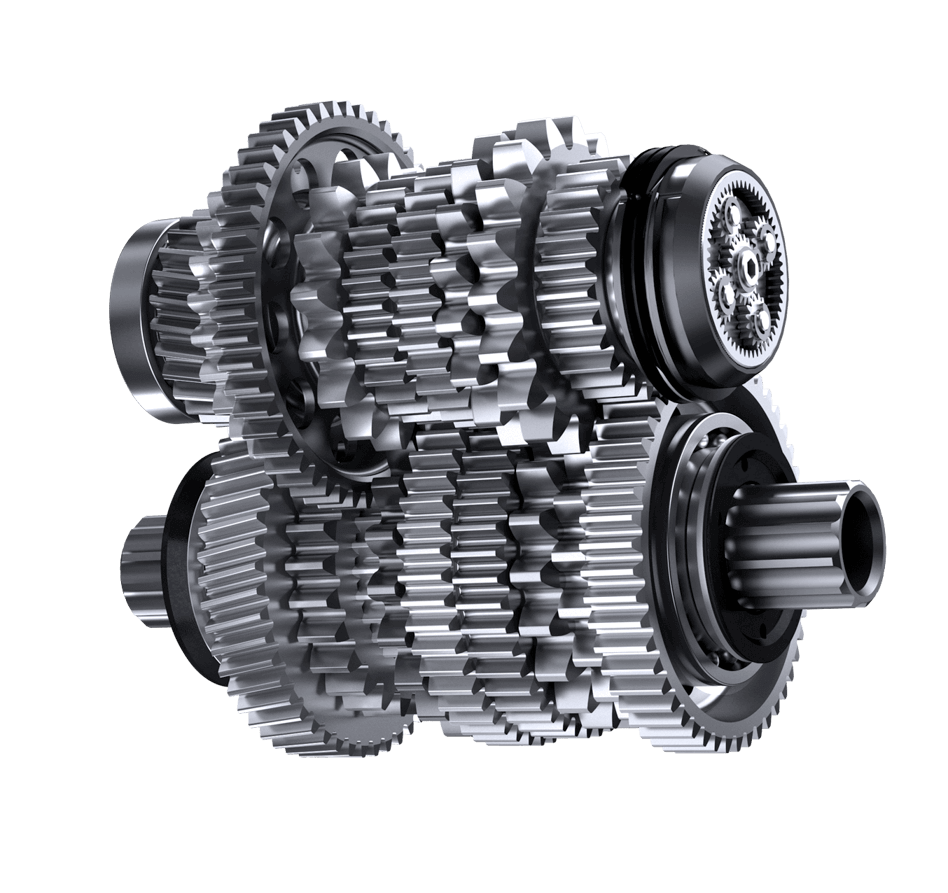

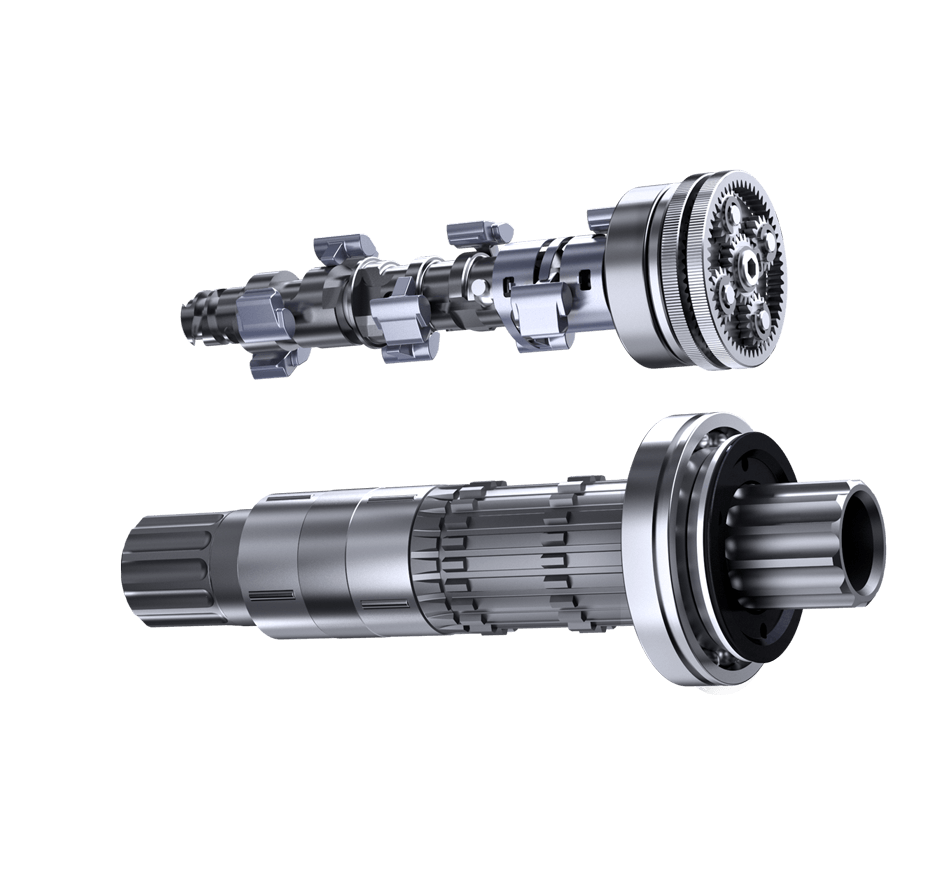

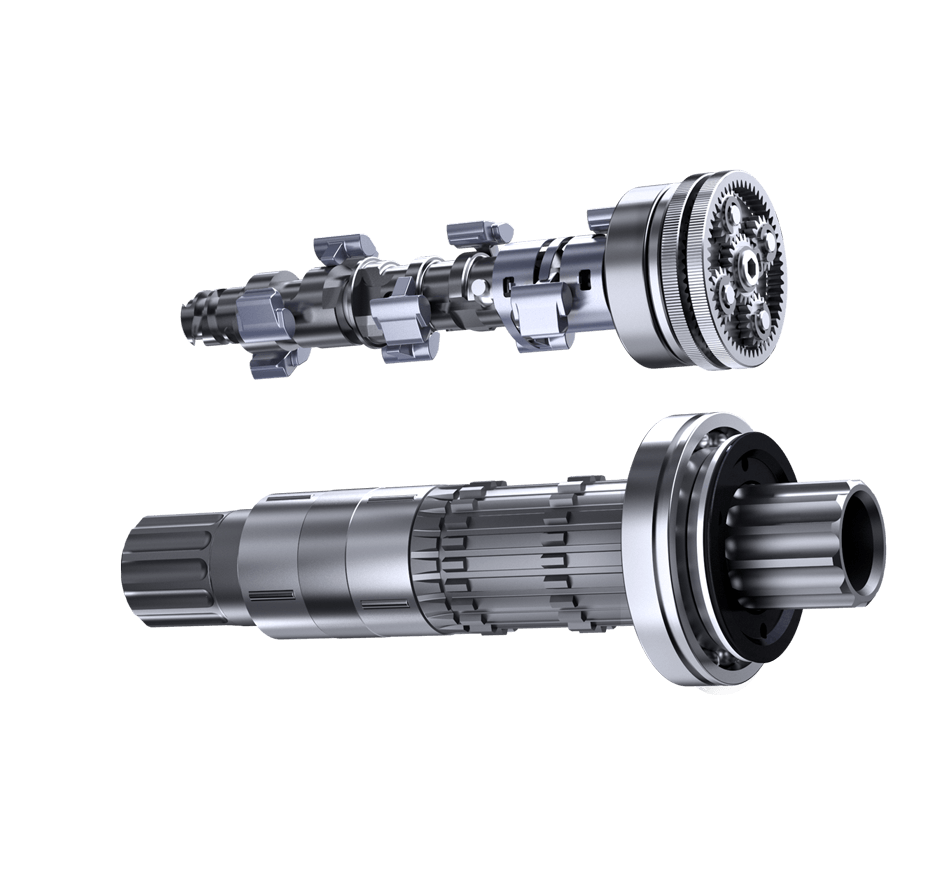

Lightning fast shifting

At the planetary gear, the rotary motion at the shift lever is transmitted directly to the camshaft in the gearbox. This controls the pawls. A rotation of the camshaft actuates the next shift pawl and engages a new gear.

Lightning fast shifting

At the planetary gear, the rotary motion at the shift lever is transmitted directly to the camshaft in the gearbox. This controls the pawls. A rotation of the camshaft actuates the next shift pawl and engages a new gear.

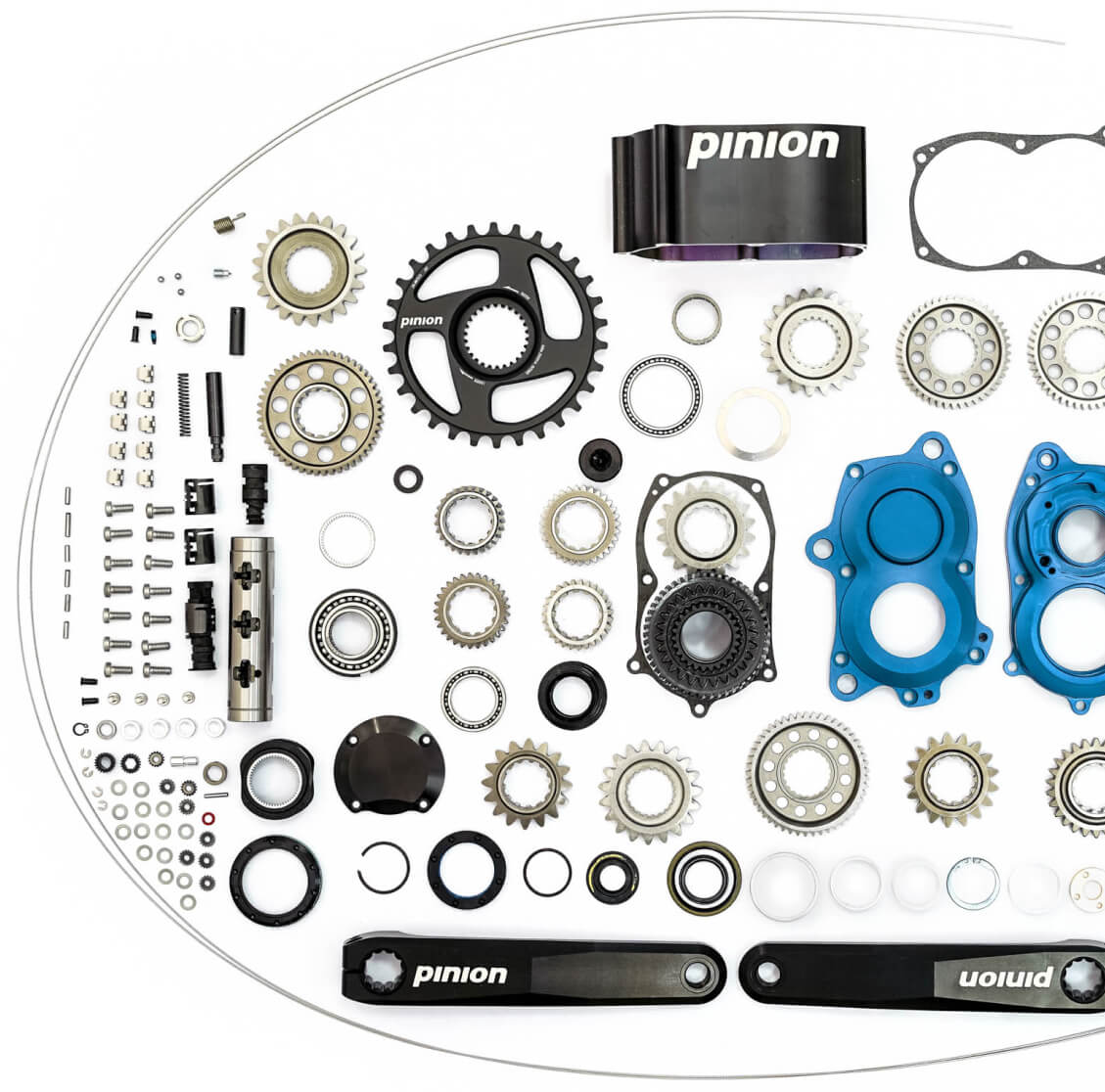

Made in Germany

Love is in the details

A Pinion P1.18 gearbox consists of 140 component pieces. From the pawls to the camshaft to the housing. Every part, no matter how small, is designed in-house and produced by automotive industry manufacturers to our specifications. With the highest precision, our experienced technicians piece together part after part, like clockwork. At the end of the assembly process, a thorough test is performed.

P-LINE

With a CNC-machined aluminum housing, up to 18 gears and unrivaled 636 % gear range, the P-Line is our flagship series.

C-LINE

With 12, 9 or 6 gears, the C-Line transmissions offer the unique Pinion ride and shift feel in a compact and lightweight magnesium housing.

Unique

DIRECT

Acclaimed

Frequenty